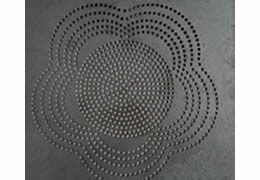

Etching Mesh

The method of etching on metal can be a chemical process using acid, a photochemical process, or an electrochemical process. The basic technique for acid metal etching is to apply a resist to the areas of a metal plate, either to the whole plate or just to the areas that one wants to remain unaffected. The parts of the metal to be etched are either not covered or the resist material is scratched off from them using tools such as an etching needle and an echoppe.

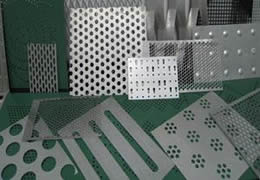

Materials: stainless steel, metal, high quality alloy plate or belt, general ply is 0.5 mm.

Production process: chemical erosion.

Technical standards: the smallest mechanical manufacture size 0.02 mm, etching area for 500mm 600mm *, material thickness of 0.02 mm - 0.5 mm.

Etching mesh technology advantage

- The mechanical production of the smallest wire diameter is 0.02mm

- The largest production area is 500mm * 600mm

- The material thickness is 0.02mm - 0.5mm

Etching mesh technology standard

- This technology improves traditional metal processing way.

- This technique can use data, charts, columnar design and other complex concave to process convex metal products.

- The etching can be used to make holes and other forms.

Fourth, the scope of application of chemical etching:

- Machinable metal types: metal, alloy and stainless steel sheet, strip steel;

- Plate thickness range: 2mm and the following sheet, especially for the under 0.5mm sheet;

- The industry uses:

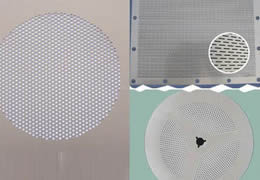

(1) Petroleum, chemical, food, pharmaceutical precision filters, filter plates, filter cartridges, filters;

(2) The electronics industry metal drain plate, cover, flat pin, lead frame,metal substrate;

(3) Precision optical and mechanical plane parts, springs parts;

(4) Bump-type friction plate and other flat parts;

(5) Metal plate and complex metal decorative panels and fine crafts.

Etching Mesh

Etching Mesh Etching Mesh

Etching Mesh Etching Mesh

Etching Mesh Etching Mesh

Etching Mesh

Product List

- Noise Barrier

- Etching Mesh

- Wind Dust Net

- Decorative Perforated Metal

- Corrugated Roofing Sheet

- Perforated Metal

- Checker Plate

- Fiberglass Wool

- Glass Wool Pipes

- Glass Wool Batten

- Gypsum Board

- Fire Wall Gypsum Board

- Vinyl Gypsum Board

- Welded Mesh Panel

- Carton Staples

- Nail

- Army Tents Series

- Camping tents

- Relief Tents Series